Technical information

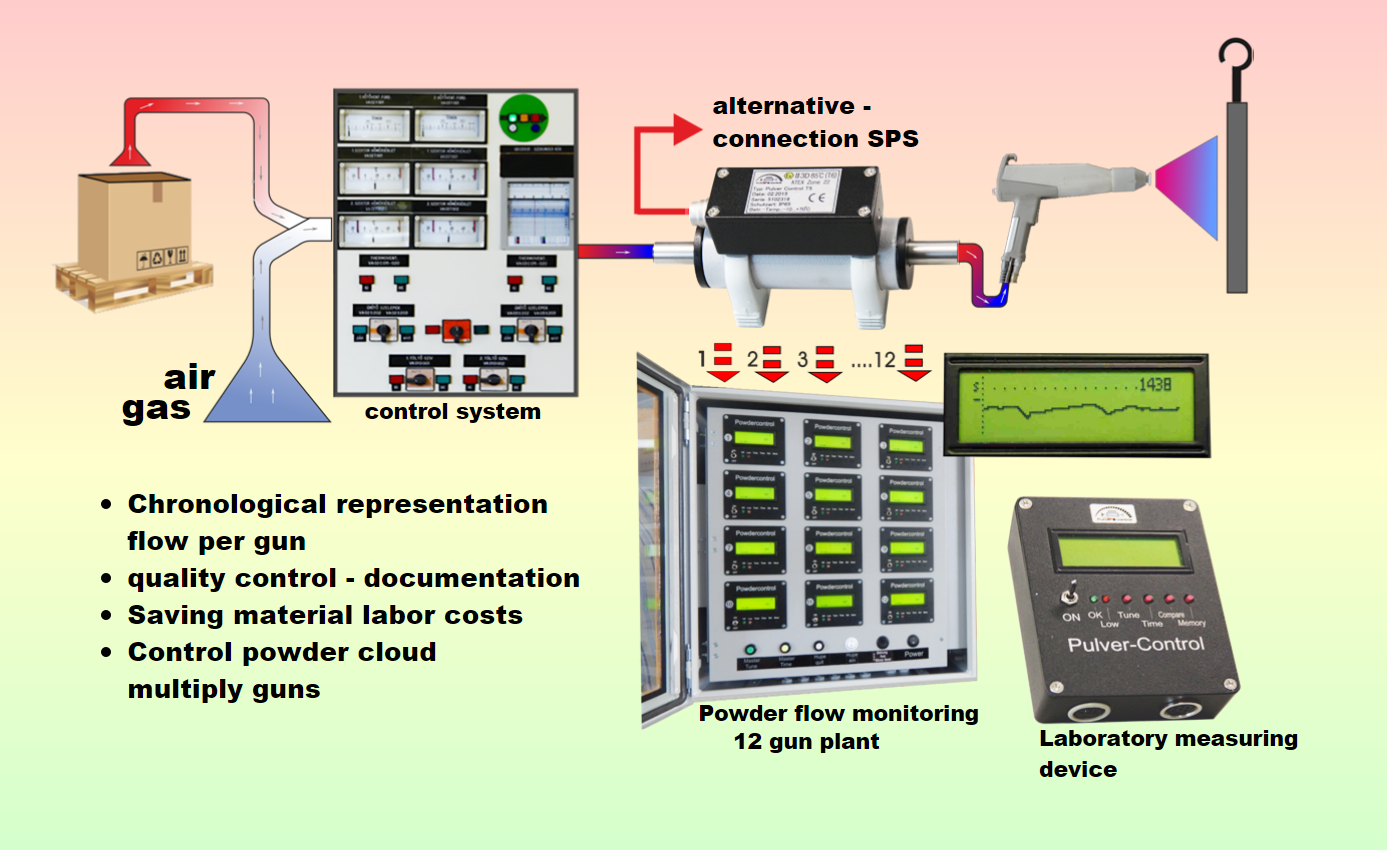

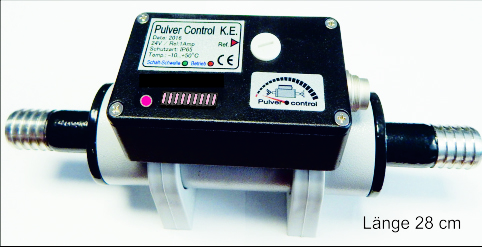

For the adaption on PLC machine control systems, we offer

additional electronics for implementation of the sensor software

RS232/0-10V voltage signal as well as 4-20 mA current output.

With our CSV-software, multiple signals can be assigned an

address serially or as a combined signal and be collected for

data analysis. Furthermore, our staff is technically equipped to

offer applications of chronological electronic interpretation

for connection to other types of sensors (temperature, time

relay of temperature monitoring in kilns, etc.).

KIESL ELEKTRONIK GmbH

Established 1987 - Development and manufacture of industrial

electronic systems. 15 years ago, a measurement system to

monitor powder ejection in coating technology was deveoped.

Easiest operation, informative display technology, Load removal

and economization of personnel and material costs as well as

quality control. Amortization of the systems in a very short

time.

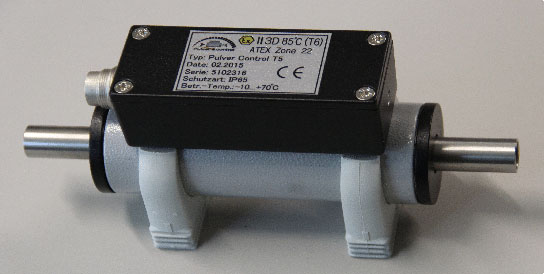

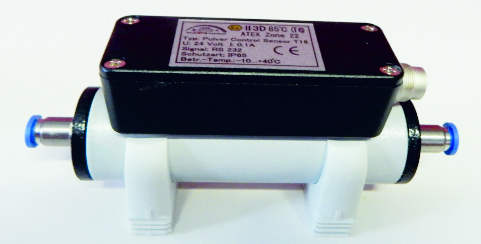

II 3D 85C (T6) ATEX zone 22

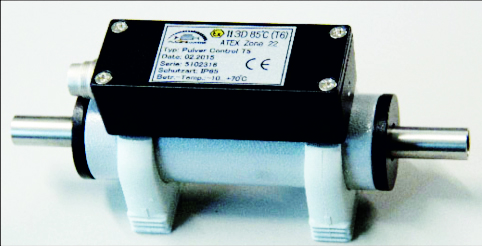

II 3D 85C (T6) ATEX zone 22